Hex Bolt Manufacturers in India: Driving Strength & Precision in Every Thread

In the world of construction, machinery, and engineering, hex bolts play a vital role. From assembling industrial structures to securing parts in heavy-duty equipment, these six-sided fasteners are known for their strength, reliability, and ease of use. As the demand for high-quality fasteners grows across sectors like oil & gas, power, infrastructure, automotive, and more, Hex Bolt Manufacturers in India are stepping up to meet global standards.

What Are Hex Bolts?

Hex bolts, also known as hex cap screws, are threaded fasteners with a hexagonal head. They’re commonly used in applications that require secure fastening with a wrench or socket. Available in various sizes, materials, and grades, hex bolts are indispensable in both heavy and light-duty applications.

Common Applications:

-

Steel and metal fabrication

-

Heavy engineering and machinery

-

Power plants and construction sites

-

Automotive and railway systems

-

Oil & gas and petrochemical industries

Why India is Emerging as a Hub for Hex Bolt Manufacturing

India has become a preferred destination for fastener manufacturing due to its robust industrial base, skilled labor force, advanced production technology, and cost-effective pricing. Here's why Indian hex bolt manufacturers are gaining global recognition:

1. High-Quality Standards

Indian manufacturers adhere to international standards like ASTM, DIN, ISO, and BS. Many have in-house quality testing facilities to ensure dimensional accuracy, tensile strength, and corrosion resistance.

2. Wide Range of Products

From standard hex bolts to custom-designed fasteners, Indian manufacturers offer a vast portfolio:

-

Stainless Steel Hex Bolts

-

Mild Steel and Carbon Steel Hex Bolts

-

Hot-Dip Galvanized Bolts

-

Zinc-Plated Hex Bolts

-

High-Tensile Grade 8.8, 10.9, and 12.9 Hex Bolts

3. Competitive Pricing

Indian manufacturing units offer cost advantages without compromising quality, making them ideal for bulk orders and international exports.

4. Customization & Timely Delivery

With CNC machining and automated production lines, top manufacturers can customize bolt dimensions, coatings, and threading options based on client specifications. Quick turnaround times and efficient logistics support also add value.

Top Industries Served by Indian Hex Bolt Manufacturers

-

Construction and Infrastructure

-

Oil, Gas & Petrochemical

-

Energy and Power Transmission

-

Automotive and Heavy Vehicle Manufacturing

-

Marine and Offshore Engineering

Key Considerations When Choosing a Hex Bolt Manufacturer

When sourcing hex bolts from India, it’s important to evaluate the manufacturer based on the following:

-

Certifications (ISO 9001, PED, CE, etc.)

-

Material traceability

-

Testing facilities (tensile, hardness, salt spray, etc.)

-

MOQ (Minimum Order Quantity) and lead time

-

Export experience and packaging standards

Future Outlook of the Hex Bolt Industry in India

As India continues to invest in infrastructure and industrial development, the demand for fasteners will only grow. Additionally, global markets are increasingly sourcing components from India due to favorable trade policies and reliability.

With the rise of “Make in India” initiatives and sustainable manufacturing practices, Indian Hex Bolt Manufacturers are poised to become global leaders in precision fastener production.

Final Thoughts

Whether you're a construction firm, machinery manufacturer, or part of a multinational supply chain, sourcing from reputed Hex Bolt Manufacturers in India ensures you get durability, precision, and performance—all at competitive prices. As India strengthens its manufacturing backbone, the country is rapidly becoming the go-to hub for all fastener needs.

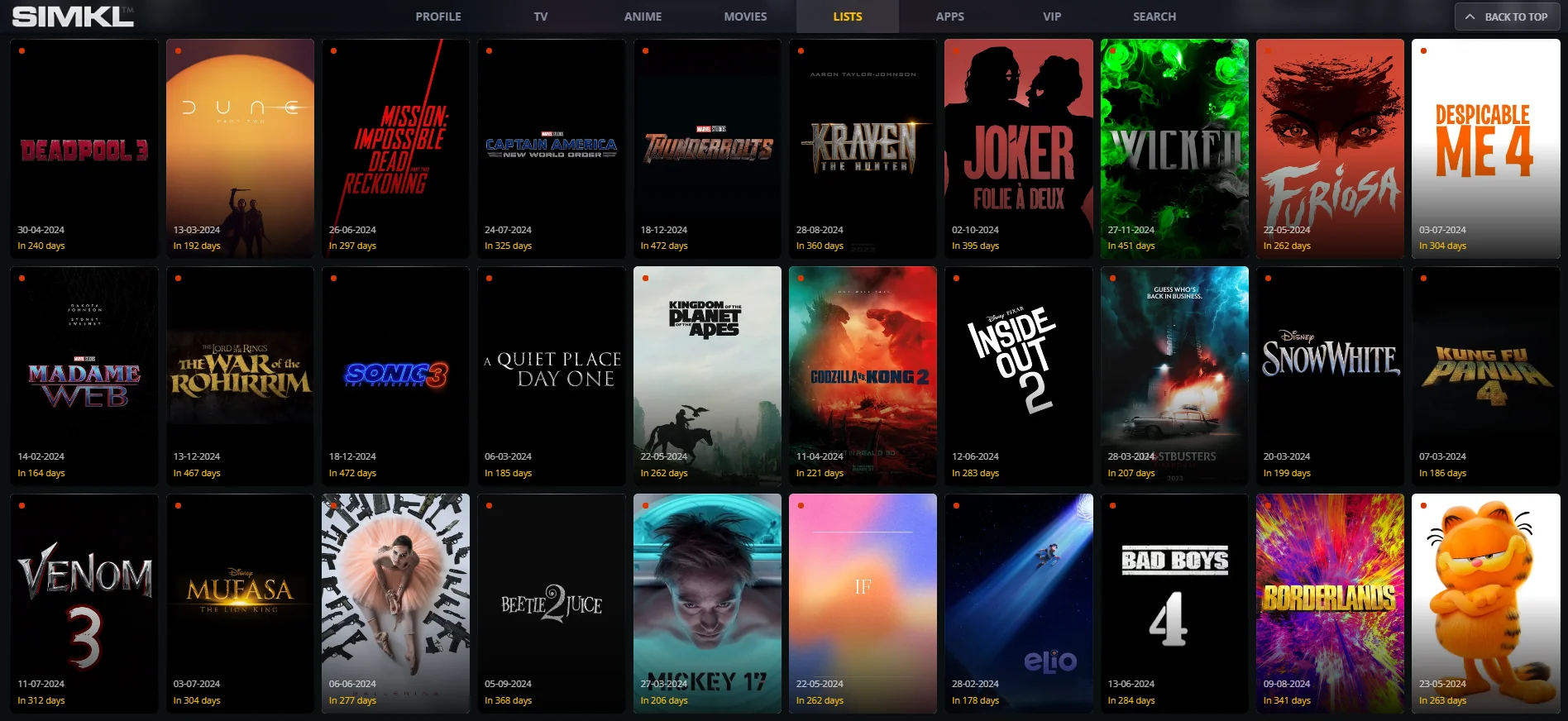

What's Your Reaction?